|

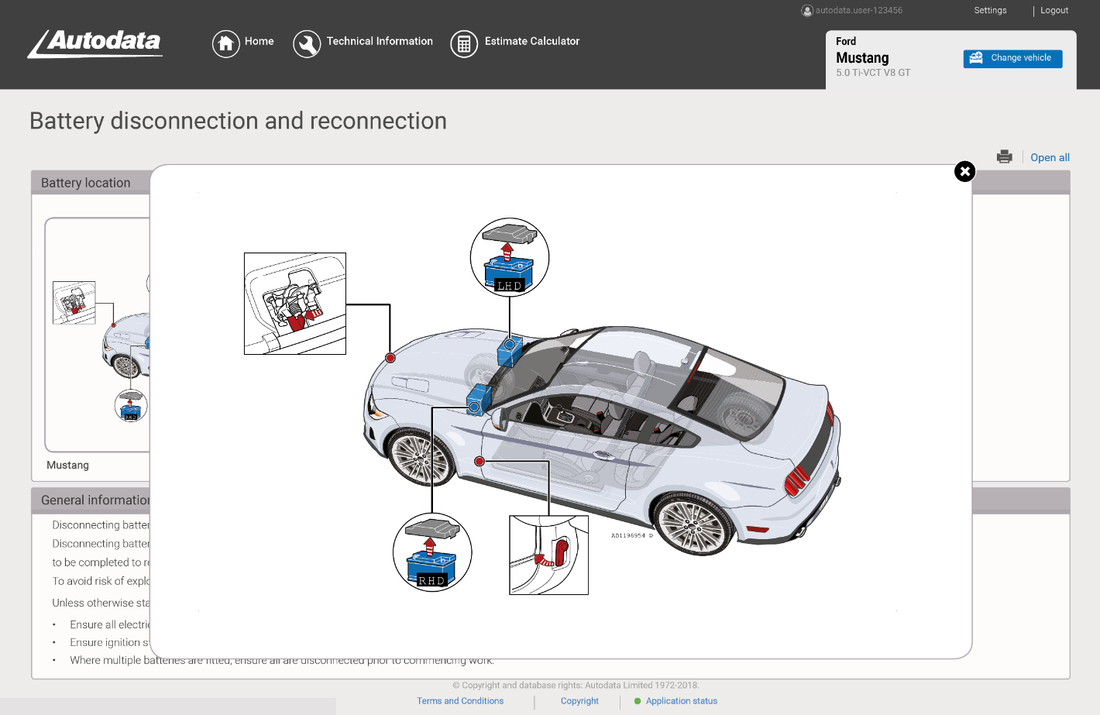

Despite the fact that preparing a vehicle for winter conditions is fairly easy, quite a few unprepared drivers visit our repair shops every winter. Every winter, between November and February, the number of vehicle breakdowns due to battery problems doubles. The most common causes of winter breakdowns are batteries, tires, brakes, lubricants and even a lack of antifreeze fluids. These are relatively simple procedures, but at the same time, selling winter vehicle inspection packages is a very profitable business for workshops. Autodata supports you with dedicated modules that precisely define the procedures for checking and replacing batteries, because this is no longer as simple as it used to be. Vehicles are becoming more and more complex and with it the procedures for changing batteries. In addition to the battery replacement procedure, you will also find diagrams in Autodata showing the locations and procedures for disconnecting the batteries; instructions for preparing the battery for disconnection and a list of electrical components that must be reset after reconnecting the battery. In addition to the battery disconnect and reconnect module, Autodata offers many other modules that are useful for winter servicing. Including electrical component locations, wiring diagrams, wheel alignment, tire pressure and tire pressure monitoring systems, and air conditioning.

Therefore, we suggest that you contact your customers and not wait for their arrival due to a breakdown. If you have a customer database, use it. Don't scare them, but get in touch and make them aware of the increased risks during winter. Establishing genuine relationships with customers is very important and the cheapest and most important marketing. Confirm that you care about them, by contacting them. A winter inspection usually includes an inspection of the following components:

Comments are closed.

|

RSS Feed

RSS Feed